In-house electronics manufacturing from scratch: How hard can it be?

Our industry needs a reboot as well, it no longer serves the people.

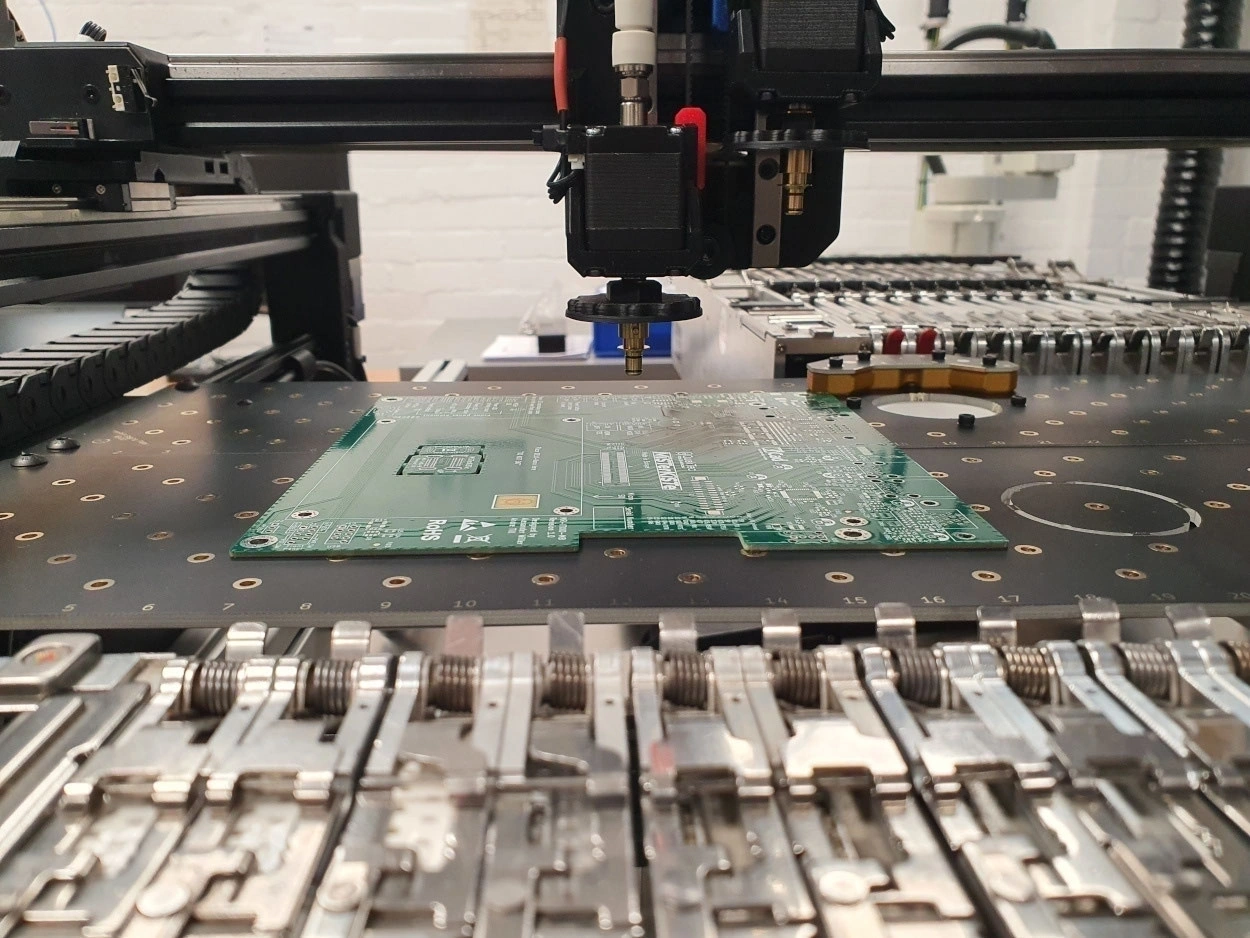

Our work is based on our belief that high-quality high-mix/low volume manufacturing of electronics in Europe is economically viable and accessible to small companies with a lower-than-expected up-front investment.

We believe that relocation of industry to Europe depends on small innovative companies, and will not come from slow and bloated industry giants whose products are victims of enshittification and maximum profit extraction.

By using open-source hardware and software whenever possible, we are attempting to set up our own production operation in Hamburg and we want to share the solutions and enable others to do the same and collectively reclaim ownership of the means of production.

We will cover:

- How we acquired and set up production machines, their costs, and our learnings

- Quirks of paste printing and reflow soldering at scale (up to 50 batches a day)

- Component inventory, tracking, DfM, etc.

- How OpenPnP is a key enabler of our prcesses

- Our proposed changes to OpenPnP

- Our work integrated Siemens Siplace Feeders in OpenPnP

Check out our ressources on the topic at https://eilbek-research.de/blog/thank-you-for-attending-our-talk-at-39c3/

Speakers of this event

Augustin Bielefeld

Electrical engineer, chip designer and motion control expert. Principal Engineer at Eilbek Research GmbH.

Alexander Willer

Electrical engineer by trade, hacker at night and Managing Director at Eilbek Research GmbH during the day. Trying to build the future I want to see. From Hamburg, interested in all things electronics, IT and mechatronics.